- Directory navigation

- Hot Products

- Hot news

- Corrugating Roller in the Core Component of Corrugating Machine

- How to innovate the manufacturing technology of corrugated machine parts?

- The Warpage of Corrugating Machine Paperboard and Its Solution

- Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

- Corrugating Machine Process

- KEYWORD

How to innovate the manufacturing technology of corrugated machine parts?

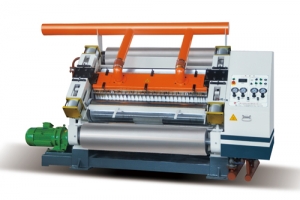

The corrugated roll of the corrugated machine is the forming die of the corrugated cardboard. It is an expensive and important part of the single-sided corrugated machine. Its corrugated teeth determine the thickness of the corrugated cardboard and the strength of the corrugated cardboard. Therefore, the corrugated rollers of the corrugated machine can only achieve high wear resistance and not easy to deform, in order to ensure that the corrugated cardboard produced meets the requirements of forming quality. In the past, after the corrugated roll surface of corrugated machine was worn out, the traditional repair method was to treat the surface with ordinary hard chromium process, and its wear resistance was not ideal.

The innovative processing technology of the corrugated roll of the corrugated machine with SiC-Cr nano-ceramic coating is that the working surface of the corrugated roll base material of the corrugated machine has SiC-Cr nano-ceramic coating of 0.08-0.10mm thickness. The SiC-Cr nano-ceramic coating consists of three layers. The first layer is the ion diffusion layer firmly combined with the corrugated roll base material of the corrugated machine, and the second layer is the first layer. The bottom layer and the outermost layer are silicon carbide-chromium nano-ceramic coatings combined with the bottom layer. The characteristics of this process are as follows: the wear resistance of the corrugated roll of this type of corrugater is about three times higher than that of the original hard chromium plated corrugater, which can improve the service life of the corrugated roll of the corrugater, reduce the time of shutdown and overhaul, and greatly reduce the production cost. The screen roller is the key component of flexographic printing, and its performance directly affects the printing quality of products.

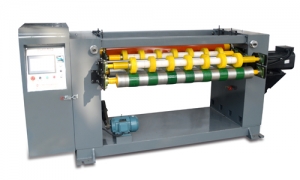

The traditional metal mesh roll of flexographic press is usually made of low carbon steel or copper, which is electronically engraved into 45 pyramidal inking holes and then chromium plated. Because the coating is thin and easy to wear, especially the scraper type ink conveying device, it is easier to wear and make the mesh hole volume smaller, which affects the printing quality of the product. Laser engraving nano-ceramic mesh roller is made of nano-ceramic material, which improves its strength, toughness and wear resistance remarkably. Therefore, laser engraving ceramic mesh roller has been widely used in flexographic printing presses. Metal mesh roller with poor performance will gradually be replaced by ceramic mesh roller with excellent performance. The nanometer properties meet the requirements of greatly improving the hardness, toughness and wear resistance of ceramics, which provides a reliable technical guarantee for making fine mesh rolls and lays a solid foundation for improving the printing quality of cartons.

Previous page:Corrugating Roller in the Core Component of Corrugating Machine

Next page:The Warpage of Corrugating Machine Paperboard and Its Solution

Corrugating Roller in the Core Component of Corrugating Machine

Publication time:2019-03-02

How to innovate the manufacturing technology of corrugated machine parts?

Publication time:2019-01-14

Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

Publication time:2019-01-14

Corrugating Machine Process

Publication time:2019-01-14

The Importance of Corrugating Machine to the Development of Packaging Industry

Publication time:2019-01-14

Importance of Preheater Setting for Single-side Corrugating Machine

Publication time:2019-01-14

Technical Key Points of Glue Coating for Single-side Corrugating Machine

Publication time:2019-01-14

Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to maintain corrugated cardboard production line

Publication time:2019-01-14

Corrugating Machine Manufacturer Chooses Chuanglian Packaging Machinery Manufacturing Co., Ltd.

Publication time:2019-01-14

What are the safety precautions for the use of single-sided corrugator

Publication time:2019-01-14

Common Problems and Solutions in Corrugating Machine Production

Publication time:2019-01-14

Rules for operation of corrugated board production line

Publication time:2019-01-14