- Directory navigation

- Hot Products

- Hot news

- Corrugating Roller in the Core Component of Corrugating Machine

- How to innovate the manufacturing technology of corrugated machine parts?

- The Warpage of Corrugating Machine Paperboard and Its Solution

- Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

- Corrugating Machine Process

- KEYWORD

- corrugating machine

Corrugating Machine Process

Corrugated cardboard is a kind of single-sided corrugated cardboard made by single-sided corrugater, which is firmly adhered to inner paper. After being transported by bridge to glue-coated composite surface paper of glue-feeding machine, it is dried in dryer and made into box board by pressing line, cutting vertically and crosswise according to production requirements.

Obviously, the waste of base paper and the low yield of cardboard products are mainly caused by the key processes of single-sided machine, conveying bridge, gluing compound, drying, vertical and horizontal cutting of liner paper. The author's opinions on the common problems and solutions in practical operation are discussed below.

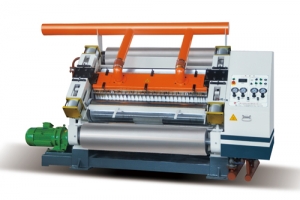

1. Single-sided Corrugator

1) When the single-sided machine starts, input the base paper. Corrugated paper and lining paper do not fit neatly.

Firstly, the output paper is skewed, which can be corrected instantaneously by speeding up the speed.

Secondly, the same side line of the liner and tile reel is not in the same line. It can be solved by "three-point-one-line method". That is to set a point on the cylinder surface of the preheater of the corrugated machine or the inner and tile paper. After the paper is put on the axle-less bracket before starting the machine, the button on the axle-less bracket is moved at one end of the tile or the inner paper, and the adjustment is made visually until the edge line of the tile and the inner paper is aligned with the setting point.

2) Base paper cracks through preheater, resulting in paper breakage.

First, the preheating area is reduced depending on the paper. When joints occur, manual traction of base paper or auxiliary force according to the direction of base paper rotation can be avoided to reduce mechanical tension.

3) When tile and lining paper are inspected by the manufacturer, a small opening of palm size is torn in the drum, and the single-sided corrugated cardboard is missing after being input into the corrugator.

Before starting the machine, prepare liner and wallpaper slightly larger than palm size (the same color, weight/M2 as the base paper on the corrugated), liner paper with a gap, liner paper with a gap, liner paper with a slight glue on the rubber plate, and then clip the gap on the front of the base paper before entering the corrugated machine. Action must be prompt, accurate, timely and safe.

4) After satisfying the production quantity, there is surplus paper head, tile paper and lining paper have more side and less side.

Normally, it is not necessary to cut off the base paper until it has been used up and then shut down. When it stops, it is necessary to cut the base paper neatly with a knife. Redundant single-sided corrugated cardboard, the next production with the same sheet, homogeneous raw paper, in the transport bridge with the new single-sided corrugated cardboard bonding good use.

In addition, it is true that there is surplus paper head parked for some reasons, which can be manually rewound onto large drums of the same specifications and quality.

5) Avoid frequent startup as far as possible, which can effectively eliminate the non-adhesive parts of paper and tile.

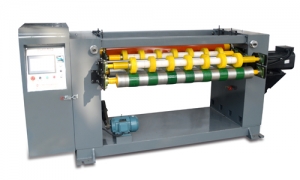

2. Transportation across bridges

1) There is too much stacking of single-sided cardboard on the bridge, and the drying locomotive is too fast or suddenly accelerated to break, and then it is not firmly bonded.

Bridge operators should pay attention to the uniform speed of the dryer, starting not too fast. When bonding the broken end, the overlap surface should follow the direction of cardboard operation, and the joint should not stop. At the same time, it should be noted that the stacking capacity of single-sided corrugated cardboard should not exceed one third of the bridge length.

2) When the width of corrugated cardboard is different from that of corrugated cardboard on one side, the paper clipper that controls the direction of corrugated cardboard is scraped.

When tile width is wide, the two clips of the clipper should be adjusted to slightly less than tile width; if the inner paper width is wide, the part wider than tile paper should be cut neatly in front of the clipper.

3) All layers of single-sided cardboard are not aligned after the dryer starts.

Before the start of the dryer, according to the size of the longitudinal trimmer side in and out, each layer of single-sided paperboard clamp is moved 2-3 cm.

3. Gluing Compound

1) Uses ordinary carton paper as facing paper according to customer's request. After preheater, the base paper becomes brittle, and then goes into the dryer and breaks. Reduce the paper force on the surface, or manually rotate the web until it is normal.

2) After entering the dryer, the edges of paper and single-sided cardboard are not uniform, and the width of emergency production paper is not uniform.

Firstly, the edges and heads of each layer can be aligned before they are fed into the dryer, and the speed of the drying locomotive can be increased when the feeding is uneven, but the uneven parts have become a waste. Whether the face paper is wider or narrower than single-sided corrugated cardboard, it must be aligned on one side.

Moreover, if the edge of the paper drum is not on the vertical line with the clip board of the paper clipper, even if the edges of the base paper and the paper heads are aligned and fed and the dryer runs at different distances. In order to solve this problem, we might as well drop a line from the side of the paper clipper conveying across the bridge to the top of the non-axle face paper support 0.5 cm away from the reel paper, point the button on the non-axle face paper support, and the edge of the adjustment paper is vertical to the line drop.

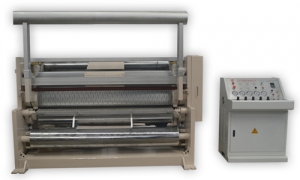

4. Dryer

1) Because of the long parking time of the dryer, a large area of paperboard is glued, especially the three-ply board.

In the production, stop as far as possible, it is necessary to stop. Operators predict the stopping time according to the situation. If the stopping time is not short (more than two minutes for five-ply board and more than half a minute for three-ply board), they should cut each layer of paper before the glue machine and open the cardboard out of the baking lane.

2) The conveyor belt of the dryer runs off, and the edge of the cardboard is glued and bonded badly.

Adjust deviation correction handwheel; check out unqualified cardboard manual bonding when stacking.

3) The temperature of drying passage of dryer is too high and the degumming of paperboard is broken. It is common in three-layer paperboard and crisp inner paper. Increase the speed of drying locomotive, at the same time exhaust steam to reduce pressure, notify the glue machine to increase the amount of glue coating according to the situation.

Previous page:没有了…

Next page:The Importance of Corrugating Machine to the Development of Packaging Industry

Corrugating Roller in the Core Component of Corrugating Machine

Publication time:2019-03-02

How to innovate the manufacturing technology of corrugated machine parts?

Publication time:2019-01-14

Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

Publication time:2019-01-14

Corrugating Machine Process

Publication time:2019-01-14

The Importance of Corrugating Machine to the Development of Packaging Industry

Publication time:2019-01-14

Importance of Preheater Setting for Single-side Corrugating Machine

Publication time:2019-01-14

Technical Key Points of Glue Coating for Single-side Corrugating Machine

Publication time:2019-01-14

Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to maintain corrugated cardboard production line

Publication time:2019-01-14

Corrugating Machine Manufacturer Chooses Chuanglian Packaging Machinery Manufacturing Co., Ltd.

Publication time:2019-01-14

What are the safety precautions for the use of single-sided corrugator

Publication time:2019-01-14

Common Problems and Solutions in Corrugating Machine Production

Publication time:2019-01-14

Rules for operation of corrugated board production line

Publication time:2019-01-14