- Directory navigation

- Hot Products

- Hot news

- Corrugating Roller in the Core Component of Corrugating Machine

- How to innovate the manufacturing technology of corrugated machine parts?

- The Warpage of Corrugating Machine Paperboard and Its Solution

- Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

- Corrugating Machine Process

- KEYWORD

- corrugating machine

Importance of Preheater Setting for Single-side Corrugating Machine

In order to ensure the preheating of single-sided corrugated cardboard with different layers, there are three or five preheaters.

In order to make the single-sided corrugated cardboard transfer uniformly and orderly, it is necessary to erect paper overpass. Let the single-sided corrugated cardboard run in accordance with the specified track before assembling. Paper flyover is mainly composed of rectification part, transmission part, tension adjustment and control device. It enables the orderly accumulation of single-sided corrugated cardboard, evaporates the moisture of single-sided corrugated cardboard appropriately, solidifies and strengthens the bonding strength of adhesives. At the same time, when the one-sided corrugating machine stops for some reason, proper accumulation will not affect the production and operation of the subsequent process.

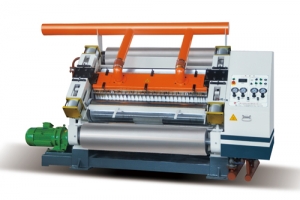

The gluing machine is a device which can make one-sided corrugated cardboard or one or more single-sided corrugated cardboard plus surface paper combine into three or more layers of corrugated cardboard by coating and adhering the whole agent. According to the processing structure of corrugated cardboard, the gluing machine is divided into single layer (three-layer corrugated cardboard), double layer (five-layer corrugated cardboard), three layer (seven-layer corrugated cardboard) and other gluing mechanisms. The glue coating device mainly consists of preheating roll, glue coating roll, floating roll, pressure roll, paper guide roll, heat insulation board, pneumatic components, glue storage tank, etc. (Fig. 15). In order to keep the synchronization of the glue coating machine in operation, its transmission is driven by a double-sided machine. When the glue coating machine rotates without load, an independent motor runs through the reducer.

The function of gluing machine is to size uniformly on the corrugated peaks of single-sided corrugated cardboard. There are specially processed mesh pyramidal pits on the rubber-coated roll, which can save glue quantity and balance glue-coated. In order to ensure better bonding quality, the working pressure of floating pressure roll controlled by pneumatic components should be no less than 0.5 MPa. Good parallelism is required for the coated roll and the scraper roll. The working gap between them is 0.25-0.4 mm.

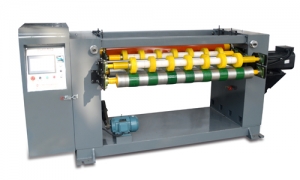

When three, five, seven or more layers of corrugated cardboard are combined, they enter the drying, setting and cooling system. This system is the double-sided machine part. The double-sided machine consists of hot section and cold section. The main function is to evaporate the moisture in the corrugated cardboard, solidify the adhesive and shape the corrugated cardboard. The heating section is composed of several groups of hot ovens side by side, and the meter is smooth and smooth. Corrugated cardboard is directly pasted on it. The special canvas belt with good permeability, certain tension and gravity and the driving roller are added on the top of the corrugated cardboard to make the corrugated cardboard heated and dried under certain pressure in operation. The heating section is divided into high temperature zone and low temperature zone. The high temperature zone makes the adhesive gelatinized and dried to enhance the bonding force. The low temperature zone dries and stabilizes the corrugated board. The function of cooling section is to distribute excess heat, uniform moisture, avoid warping, and make corrugated cardboard smoothly enter the next process.

Previous page:Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

Corrugating Roller in the Core Component of Corrugating Machine

Publication time:2019-03-02

How to innovate the manufacturing technology of corrugated machine parts?

Publication time:2019-01-14

Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to choose corrugated base paper

Publication time:2019-01-14

Corrugating Machine Process

Publication time:2019-01-14

The Importance of Corrugating Machine to the Development of Packaging Industry

Publication time:2019-01-14

Importance of Preheater Setting for Single-side Corrugating Machine

Publication time:2019-01-14

Technical Key Points of Glue Coating for Single-side Corrugating Machine

Publication time:2019-01-14

Chuanglian Packaging Machinery Manufacturing Co., Ltd. teaches you how to maintain corrugated cardboard production line

Publication time:2019-01-14

Corrugating Machine Manufacturer Chooses Chuanglian Packaging Machinery Manufacturing Co., Ltd.

Publication time:2019-01-14

What are the safety precautions for the use of single-sided corrugator

Publication time:2019-01-14

Common Problems and Solutions in Corrugating Machine Production

Publication time:2019-01-14

Rules for operation of corrugated board production line

Publication time:2019-01-14